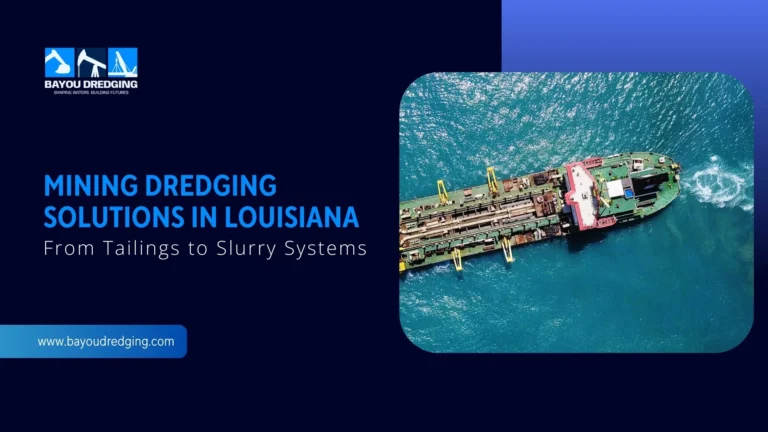

In the world of modern dredging, having the right equipment is crucial for maintaining waterways, expanding ports, reclaiming land, and extracting valuable resources. One of the most critical tools for large-scale and offshore sediment removal is the dredge barge. But what exactly is a dredging barge, and how does it differ from other dredging platforms? This guide explains everything you need to know about dredge barges—including their components, types, and operational benefits—with special attention to specialized configurations like the sand dredging barge used in coastal and sand mining applications.

What Is a Dredge Barge?

A dredge barge is a flat-bottomed floating platform specifically designed to support and execute sediment removal operations in aquatic environments. Unlike self-propelled dredge boats, a dredging barge typically remains stationary during operation, using spuds or anchors to maintain its position. At the same time, heavy-duty pumps, cutterheads, or excavator arms remove silt, sand, or debris from the waterbed. These barges are essential in large-scale or deep-water dredging projects where stability, onboard capacity, and equipment integration are critical.

When compared to mobile dredging platforms like dredge boats, dredge barges offer greater load-bearing capacity and can accommodate larger or more powerful dredging equipment. While dredge boats are ideal for their maneuverability and rapid deployment, a dredging barge provides a stable and scalable platform suitable for extended, high-volume dredging operations.

Dredge barges are used in both inland water bodies, such as rivers, lakes, and reservoirs, as well as in offshore environments, including ports, coastal restoration zones, and marine infrastructure projects. Their versatility allows them to support a wide range of operations, from navigation channel maintenance to sand mining.

In some regions, the term “san dredging barge” may refer to specialized dredge barges used in sand reclamation or offshore sand extraction applications. While functionally similar to standard dredging barges, san dredging barges are typically outfitted with systems optimized for high-volume sand removal, making them ideal for beach nourishment and aggregate supply.

How a Dredge Barge Works

A dredge barge operates as a stable, floating platform equipped to support a range of dredging technologies for removing sediment, debris, and other materials from the bottom of rivers, lakes, harbors, and offshore environments. Its operational setup centers on positioning the barge at a designated site—either anchored or stabilized using spuds—where it serves as the foundation for all sediment extraction activities.

Depending on the configuration, a dredging barge may be outfitted with powerful cutterheads, submersible or suction pumps, and hydraulic arms to break up and remove sediment. These components are connected to discharge pipelines, which transport the dredged material to a disposal area, dewatering site, or reclamation zone. The barge may also incorporate winch systems for repositioning or tensioning cables, especially in environments where precise movement control is necessary.

Some setups involve onboard booster pumps or are connected to remote booster stations to facilitate the transportation of material over long distances. A dredge barge may also feature mounted excavators or cranes for mechanical dredging, depending on the sediment type and site access. In more specialized operations, such as those involving sand extraction, a sand dredging barge is used, often equipped with high-throughput sand pumps and systems optimized for continuous sand discharge.

Whether in inland waterways or offshore construction zones, the strength of a dredge barge lies in its ability to host heavy-duty equipment and facilitate consistent, high-capacity dredging operations with maximum efficiency and control.

Core Components of a Dredging Barge

A dredge barge is a highly engineered platform built to handle the physical demands of sediment removal in a wide range of aquatic environments. Each dredging barge integrates several core components that work together to deliver reliable, high-volume performance for industrial, municipal, and environmental dredging operations.

At the foundation is the hull and deck structure, typically flat-bottomed to ensure maximum stability during dredging. This provides a solid platform for mounting heavy machinery and withstanding variable water and sediment conditions. The deck is designed to accommodate mounts or arm supports for dredging equipment, which hold cutterheads, hydraulic booms, or excavator arms used for breaking up and removing sediment from the waterbed.

Key to the dredging process is the pumping system or pipeline discharge assembly. A dredge barge typically incorporates large-capacity slurry or sand pumps, which transport dredged material through discharge pipelines to shore-based dewatering facilities or offshore disposal sites. In the case of san dredging barges, the pumping systems are typically optimized for continuous sand extraction and high-solids throughput.

Powering these operations is a power source, which may include diesel engines, electric motors, or onboard generators, depending on the barge’s size, location, and environmental constraints. For complex or remote projects, the barge may also include integrated booster pumps to increase the distance for material transport.

Additional critical components include operator cabins for system monitoring and control, spuds that provide anchoring and stability during dredging, and winch systems used for barge repositioning and anchoring adjustments. Essential safety gear, including railings, lighting, emergency systems, and onboard communication tools, ensures safe operation in both marine and inland environments.

Together, these components make the dredge barge a robust and versatile asset, capable of supporting high-efficiency sediment removal across a range of challenging dredging scenarios.

Common Types of Dredge Barges

There are several types of dredge barges, each designed to meet specific operational needs based on dredging method, site conditions, and project scale. Choosing the right configuration is crucial for maximizing productivity and adapting to diverse sediment types, varying water depths, and environmental constraints.

A spud barge is one of the most widely used forms of dredging barge. It remains stationary during operation thanks to long, vertical steel shafts called spuds, which anchor the barge to the waterbed. Spud barges offer a stable platform for cutter suction dredging, submersible pumps, or mechanical dredging tools, making them ideal for use in ports, rivers, and inland waterways.

Hopper barges are specialized for transporting dredged material to disposal or processing sites. Rather than performing the actual excavation, these barges are towed or self-propelled and used in tandem with active dredging units. Once filled with sediment, the hopper barge travels to a designated dump location, where it can release its load via bottom doors or mechanical unloading systems.

An excavator-mounted dredge barge features a hydraulic excavator secured on the deck. This setup is particularly useful for mechanical dredging of coarse materials, debris, or sediment in confined or shallow areas. It’s also a cost-effective solution for small-scale dredging operations that don’t require complex pumping systems.

Cable-driven or crane-supported dredge barges are used in deeper or high-volume dredging operations, where a crane or winch system operates dredging tools—such as clamshell buckets, draglines, or operating grabs—into the sediment. These barges are highly effective in industrial ports and offshore sites, particularly in areas with heavy or compacted material.

Finally, modular dredging barges are ideal for shallow, narrow, or environmentally sensitive areas. These barges are constructed using interlocking pontoons that can be easily transported and assembled on-site, providing access to remote or hard-to-reach areas. Some san dredging barge configurations use this modular design when working in restricted coastal zones or sand reclamation sites.

Each type of dredge barge plays a distinct role in ensuring safe, efficient, and compliant sediment removal, supporting a range of applications from channel maintenance to marine infrastructure development.

Key Applications of San Dredging Barges and Others

Dredge barges are essential tools in a wide range of marine and inland projects that require efficient, large-scale sediment removal. From heavy-duty industrial use to environmentally sensitive operations, both standard and specialized dredging barge configurations are deployed worldwide to enhance waterway functionality, maintain ecological balance, and facilitate land reclamation.

One of the most common applications is port and harbor deepening. Over time, sedimentation reduces navigable depth, making it difficult for large vessels to access shipping terminals. A dredging barge equipped with high-capacity pumps or cutter systems is used to restore the required depth levels and ensure safe and efficient maritime traffic.

River and canal maintenance is another vital use case. Sediment buildup in these waterways can lead to flooding, erosion, and navigational blockages. By deploying a dredge barge, municipalities and water management agencies can maintain consistent flow, protect infrastructure, and prevent seasonal water level issues.

In environmental dredging, dredging barges are used to remove contaminated sediments from riverbeds, lakes, and industrial lagoons. These operations require precision and turbidity control, which is often achieved using GPS-guided systems and enclosed discharge pipelines mounted on the barge. The goal is to isolate and remove pollutants without disturbing nearby ecosystems.

Mining and reclamation projects often rely on dredge barges to extract valuable materials, such as sand, gravel, or minerals, from underwater deposits. A san dredging barge, in particular, is optimized for high-throughput sand extraction, often used in aggregate production or land expansion efforts.

Finally, coastal restoration and sand replenishment projects depend heavily on san dredging barges. These barges are equipped to dredge sand from offshore sources and deposit it along eroded shorelines, protecting against storm surge, rising sea levels, and habitat loss. Their ability to operate in dynamic marine environments makes them a critical asset in coastal engineering and environmental defense.

With their broad utility, dredge barges—including specialized sand dredging barge units—play an indispensable role in both commercial development and environmental preservation efforts worldwide.

Advantages of Using a Dredge Barge

A dredge barge offers numerous advantages that make it the go-to solution for high-volume and complex dredging operations. Its design allows for powerful, continuous sediment removal, making it highly effective in projects where material buildup is extensive or persistent. Equipped with large-capacity pumps or excavators, a dredging barge such as this moves and removes massive volumes of silt, sand, or debris with speed and precision, significantly reducing project timelines.

One of the key strengths of a dredge barge is its versatile deployment across a wide range of environments. Whether in shallow inland waterways or deep coastal zones, dredging barges can be configured to match site-specific requirements, ranging from spud barge stabilization in rivers to modular units for hard-to-access reservoirs. Specialized setups like the san dredging barge are tailored for high-efficiency operations in offshore sand mining or beach nourishment, demonstrating their adaptability across varying water types and depths.

In addition to performance, cost-efficiency is a major benefit. For large-scale or multi-phase projects, a dredge barge provides a centralized platform that reduces the need for multiple machines, crew transfers, or shoreline access. Its continuous operation and on-board capacity minimize downtime and transportation costs, especially when integrated with hopper-style barges that carry dredged material directly to disposal or fill sites.

A modern dredging barge also supports environmental compliance through advanced monitoring and precision dredging tools. With features such as GPS, sonar, and turbidity control systems, dredge barges minimize habitat disruption and reduce sediment plume spread, making them an ideal choice for environmentally regulated zones.

Lastly, when configured with hoppers or sealed containment, a dredge barge can transport material on-site, eliminating the need for additional transfer vessels. This streamlines workflows, particularly in offshore or long-distance reclamation projects, and enhances the overall efficiency of sediment handling and disposal.

Dredge Barge vs Dredge Boat: What’s the Difference?

Although both are essential tools in sediment removal operations, a dredge barge and a dredge boat differ significantly in terms of design, mobility, and application. Understanding these distinctions is critical when determining the right equipment for your dredging project.

A dredge barge is generally a stationary or towed platform, built for stability and equipped to support large-scale or high-volume dredging systems. These platforms are often anchored using spuds or mooring systems and serve as the base for heavy equipment, such as cutterheads, submersible pumps, or excavators. Dredging barges are ideal for deepwater, offshore, or extended operations where size, capacity, and power are critical. Specialized configurations, such as a san dredging barge, are specifically built for offshore sand mining and beach nourishment projects, offering exceptional throughput and durability in harsh marine environments.

On the other hand, a dredge boat is typically self-propelled and mobile, making it well-suited for small to mid-sized operations where agility is more important than raw capacity. Dredge boats can quickly relocate, making them ideal for applications like pond dredging, marina maintenance, or emergency sediment removal in confined or shallow waters.

Choosing between a dredge barge and a dredge boat often comes down to the project scope, site conditions, and required equipment size. While dredging barges offer unmatched stability and equipment flexibility for large, long-duration projects, dredge boats are a practical option for short-term, mobile, or space-limited jobs.

Factors to Consider Before Choosing a Dredge Barge

Selecting the right dredge barge requires a thorough assessment of site-specific and project-related variables to ensure efficient and cost-effective operation. Not all dredging barges are created equal, and selecting the wrong setup can lead to delays, regulatory issues, or performance inefficiencies.

Start by evaluating site conditions, including water depth, sediment type, and current strength. For example, fine silts in shallow, slow-moving waters may require a compact modular barge, while dense sand in deep or tidal zones may call for a larger, more robust san dredging barge equipped with heavy-duty pumps and stabilized anchoring systems.

Next, consider the scale and duration of the project. A multi-phase port expansion or coastal reclamation effort will benefit from a high-capacity dredge barge capable of supporting continuous, long-term operations. Smaller or short-term jobs may not justify such a large platform.

Equipment compatibility is another critical factor. Your dredging barge must accommodate the right type of dredge pump, cutterhead, or hydraulic excavator and allow for seamless integration with discharge pipelines, booster pumps, or material handling systems. Ensuring that your dredge barge supports the operational requirements of your tools will maximize dredging productivity.

You’ll also need to consider transportation and mobilization. Some dredging sites may be remote or difficult to access, in which case a modular dredging barge—designed for transport by truck or in shipping containers—may be preferable to a single-piece steel hull barge that requires crane lifting or marine towing.

Finally, don’t overlook regulatory and environmental factors. In sensitive areas, such as marine reserves or urban waterways, you may need a dredge barge with turbidity control systems, GPS-guided positioning, and low-emission power sources to comply with local and federal guidelines.

Carefully weighing these considerations ensures that your chosen dredge barge—whether it’s a standard platform or a specialized san dredging barge—delivers the best performance, safety, and environmental compliance for your specific dredging operation.

Conclusion

Whether you’re tackling deepwater harbor dredging, environmental cleanup, or offshore sand reclamation, a dredge barge provides the capacity, stability, and versatility needed to handle demanding dredging projects. By understanding the different types of dredging barges, how they operate, and what factors to consider before deployment, you can make informed decisions that align with your project’s technical and regulatory requirements. From inland rivers to coastal restoration zones, the right dredge barge—including high-performance options like the San dredging barge—can be a game-changer in achieving efficiency, compliance, and long-term operational success.